Vision and Verification

A vision inspection system

"CoLOS® Software has enabled management of the entire fleet from a central point, leading to real productivity gains. "

Pre-Sales and Sales Engineers, Markem-Imaje

Product Inspection

Conduct thorough checks based on product orientation, seal, cap seating, gaps, kitted/set, color, defects/damage, misalignment, and more. Ensure accuracy and quality, minimizing errors and waste due to inaccuracies. Verify products meet specifications, reducing the risk of costly rework, returns, and reputational damage.

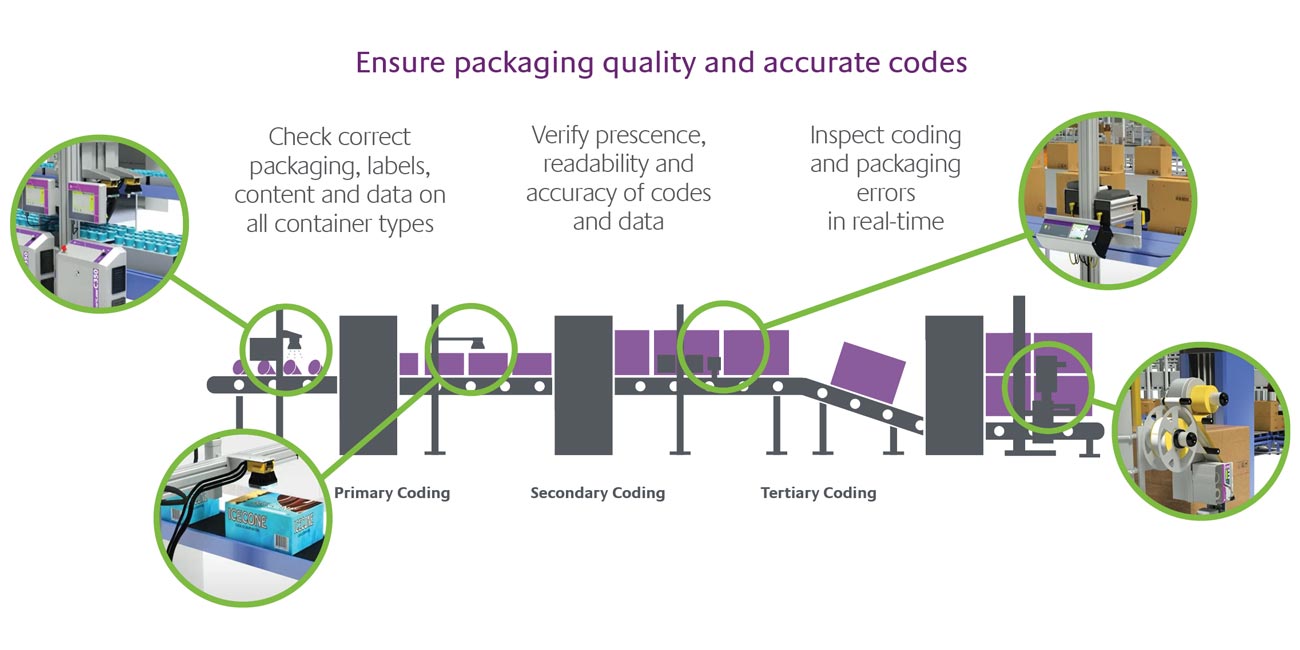

Coding Integrity

Check presence/absence or partial presence of codes and verify 1D/2D codes, grade the barcode, and check print quality. Ensure accuracy on variable backgrounds such as curved, bright, low-contrast, reflective, uneven, and metallic backgrounds, minimizing waste and errors due to coding inaccuracies.

Packaging Integrity

Verify packaging material for correctness, detect damaged packaging, and ensure compliance with regulations and product specifications. Match packaging with products on the production line using preprinted data or ERP/database. Prevent waste and errors from incorrect or unacceptable packaging materials, ensuring seamless production and delivery.

Benefits

Ensure brand protection by minimizing compliance risks.

Faster and efficient production due to automated checks, inspection and verification.

Ensure brand protection by minimizing compliance risks.

Industries—from production to distribution

Beverage

Food

Automotive

Cosmetics

Construction

Here's what our customers are saying about our software solutions

"CoLOS® Software has enabled management of the entire fleet from a central point, leading to real productivity gains. "

Pre-Sales and Sales Engineers, Markem-Imaje

"With CoLOS® software, we can send item number, batch number, and more to our marking systems without any error."

Head of Packaging, Innovation & Cosmetics, Topfer

"CoLOS® software gave us a powerful information management tool to link the message database and printers. This helped us eliminate human-related errors significantly."

Operations Manager, Lapp Kabel