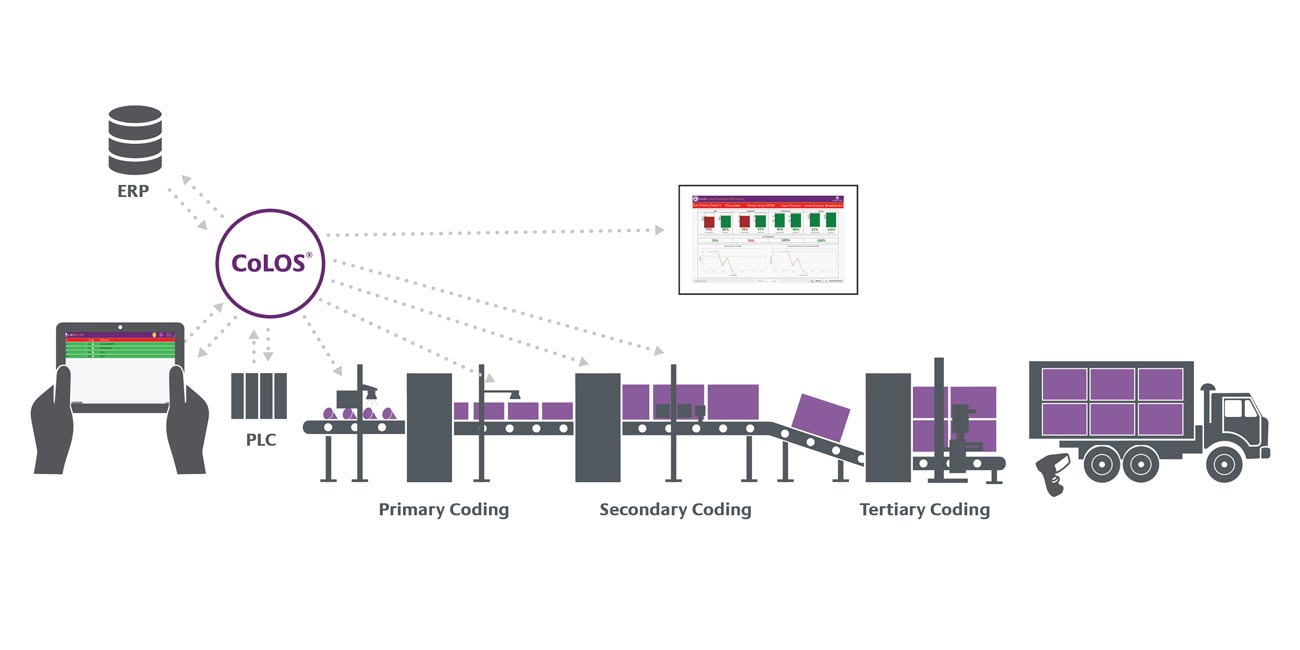

Line Control and KPIs

Master data management solution

"CoLOS® Software has enabled management of the entire fleet from a central point, leading to real productivity gains. "

Pre-Sales and Sales Engineers, Markem-Imaje

Set up devices with ease

Automate message inputs to fields, message printing, seamless communication back to ERP systems, and selecting production orders with a single touch. Eliminate errors caused by manual typing, ensuring accuracy, efficiency, and streamlined production workflows.

Data Management

Centrally manage Printer performance and OEE data by configuring workflows for proactive maintenance, troubleshooting, receiving alerts on faults and incidents, identifying bottlenecks, and more. This provides real-time insights into production data and losses that help in making informed decisions for continuous improvement.

Reporting and Decision Making

Unlock actionable insights with comprehensive reports on utilization, volume, speed, fault, ink usage, print quality, printer availability, line performance, and downtime analysis. Make proactive, data-driven decisions to optimize production, reduce waste, and improve overall equipment effectiveness (OEE).

Benefits

Make data-driven decisions for maintenance and enhance quality of production.

Identify areas for improvement and optimize production workflow.

Reduce downtime and losses.

Industries—from production to distribution

Beverage

Food

Automotive

Cosmetics

Construction

Here's what our customers are saying about our software solutions

"CoLOS® Software has enabled management of the entire fleet from a central point, leading to real productivity gains. "

Pre-Sales and Sales Engineers, Markem-Imaje

"With CoLOS® software, we can send item number, batch number, and more to our marking systems without any error."

Head of Packaging, Innovation & Cosmetics, Topfer