What’s the best coding technology for your GS1-128 barcodes?

What’s in a barcode?

- Global Trade Identification Number (GTIN)

- Global Location Number (GLN)

- Lot / batch / serial number

- Best-before / Sell-by dates

- Net weight / dimensions

- Serial Shipping Container Code (SSCC)

How can I comply with GS1-128 standards?

This has led to an increased interest in robust software solutions to avoid waste from misprinted information. Here are the key points for picking the right coding solution:

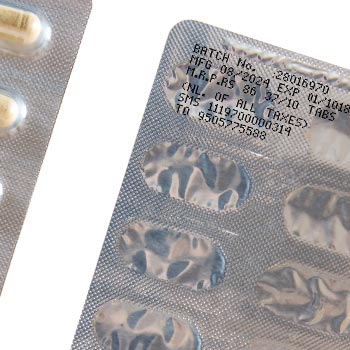

1. Consider the packaging material

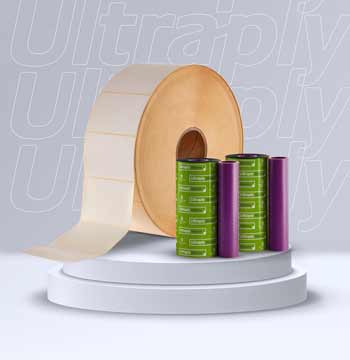

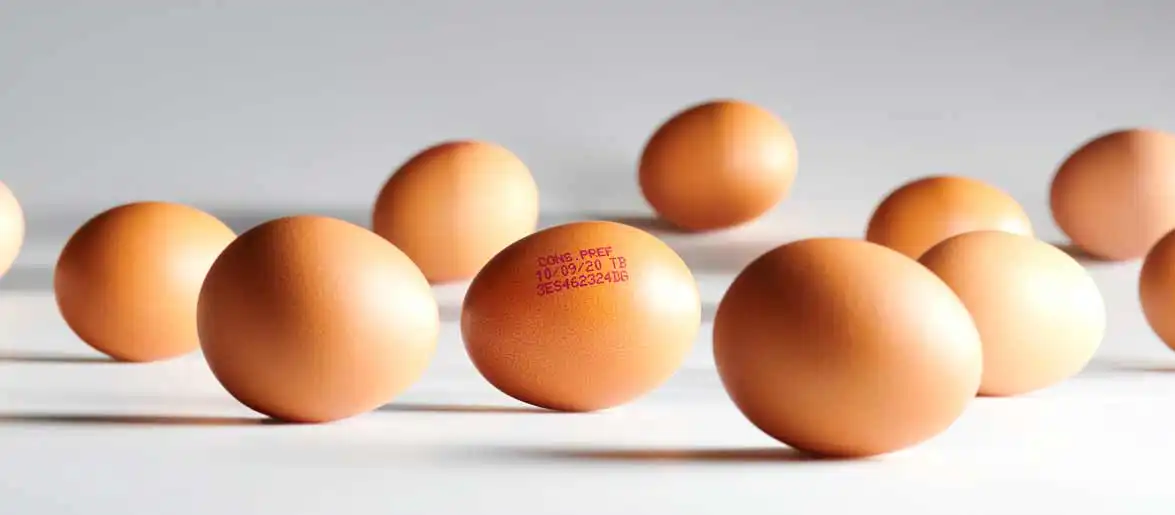

- Print and apply labeling is the most prevalent option for GS1-128 codes, accommodating the widest range of materials and shapes since the product surface is less important when using labels. In line with the GS1-128 recommendation to use two labels, there are print and apply labeling systems on the market that print on front and side without requiring costly line modifications. This option works on curved or uneven surfaces and is the only choice for shrink- and stretch-wrapped products. It is essential that the system ensures grade C ANSI or better with 300dpi print quality.

- In certain circumstances an inkjet printer can be used to print directly onto cases, with the advantage of eliminating label costs. This is possible if the material is light in colour, with a reflectance of 43.3 or higher, such as corrugate made from bamboo, material with low recycled content, etc. Note that systems with liquid inks are unsuitable as they struggle to meet the required ANSI grade. Choose a solution with solid inks that can print in 200dpi resolution directly onto cases. For example, solid wax-based inks ensure the code dries immediately on contact and will not spread on either porous or non-porous packaging. The coding technology and inks must guarantee grade C ANSI codes.

- In the case of brown packaging, either a white area can be printed on first and the barcode applied in that space, or the barcode can be printed directly on the brown background with high optical density inks.

2. Use GS1-128 compliant printers and software

- There is little point in having the right printing equipment and consumables to generate good quality GS1-128 barcodes on your packaging if the actual information being encoded is flawed. There are many points along the chain at which human error can introduce non-compliant data into the barcode. An end-to-end software solution with GS1-128 parameters built in will flash an error warning if operators attempt to input invalid information at any stage of the production process.

- Overall operational efficiency is also improved by tight integration with company systems, allowing seamless and accurate data exchange between Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), while validating that encoded data meets GS1-128 specifications.

- The most advanced systems on the market also include automated job set-up and a data-design wizard to prevent invalid input, enhanced with vision systems to ensure that every product leaves the factory with a compliant barcode.